Lifestyle

Factory.

Your Full-Service

Production Partner.

In an international comparison, we not only make Germany a competitive production location, but we are one step ahead! On request, we accompany you from the idea to the delivery of the realized products. In addition to its own brands, such as Monomania, LIFESTYLE FACTORY also develops and produces small and large series for numerous international customers. Due to its many years of experience, the LIFESTYLE FACTORY is one of the leading manufacturers of jewellery, watches, accessories and components in Europe, with a strategically convenient headquarters in Eching, not far from Munich Airport.

We have been processing metal in the precision field for over 30 years. Originally based in the high-end watch and jewellery industry, our state-of-the-art machinery is now compatible with all high-precision applications. We offer the manufacture of precision mechanical components as well as components for all industries, for example for projects from automation, electrical/ electronics, medical technology, tool technology, aerospace, automotive, watches, jewelry, accessories and many more. Our machinery is always of the current generation and promis excellent performance in terms of precision, efficiency and reliability. We realize components of the highest complexity, through automated CAD systems rapid checks of project are feasible, prototype construction as well as adjustments and changes in a short time.

We work according to a sustainable Code of Conduct, which corresponds to the RJC (Responsible Jewellery Council) Code of Practice. The RJC is a non-profit organization founded with the aim of ethical, social and ecological responsible practices that respect human rights throughout the supply chain for jewellery made from diamonds, gold and platinum metals, from mining to retail. We are a voluntary member and regularly get certified, because we have the aim to take responsibility for our actions.

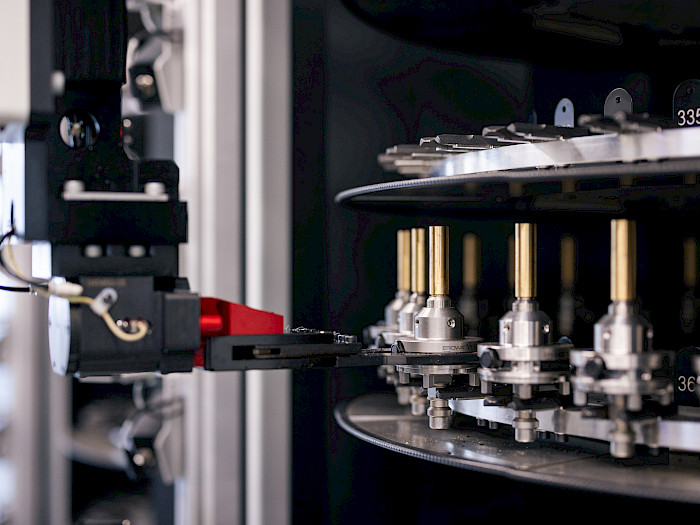

Both in development and production we work with connected CAD systems, which already show the machinery feasibility on the screen of the design team. We operate state-of-the-art turning and milling machines of the latest generation, which are automatically supplied with material via efficient 3m bar loaders. The individual stations of production and high-performance laser systems are connected via robot lines and work 24/7. Sandblasting machines, automatic polishing systems and painting chambers are available for surface processing. PVD coatings, galvanic finishes and other trades we realize with trusted partners in the immediate vicinity.

Our main materials are metals and precious metals, but they are also often combined with other materials to meet aesthetic or functional requirements in symbiosis. We process all types of hardness, including extremely hard steels. Therefore, our machinery can also handle softer metals such as aluminium, brass, copper, silver or gold without any problems and with highest efficiently. We use a sustainable supply chain that respects human rights in all materials we source for our production. For precious metals such as gold, silver, platinum and palladium we are even voluntarily audited and certified according to the 'Chain of Custody' of the Responsible Jewellery Council (COC:2019).

We conduct regular analyses of our energy efficiency. In this context, major savings were achieved through more efficient lighting, optimization of the machine park and more responsible action in daily business. The environmental impact is further reduced by purchasing mostly renewable energy.